Comparison of Beijing Grip Couplings and Flange

发布日期:2016-04-12

Traditional pipeline connection and repair methods mainly use welding, flange and other methods, so there are very big hidden dangers in many aspects of operation, such as coal mine, natural gas pipeline, oil pipeline and so on. Moreover, traditional pipeline connection & repair methods need a lot of work space, and large construction vehicles should be used when necessary to enter the work site. Grip pipe coupling and repair clamps has the following advantages:I. Universal/Compatibility:

1. It is suitable for connecting pipes of the same or different material, thin or thick wall, and compatible with other traditional connection modes.

2. The allowable diameter direction of two pipes with different diameters is 4 mm different.

3. There are some dislocations between the pipelines. When the axis has a deviation angle, it can be used normally, so the problem of pipeline correction can be avoided.

4. It can also be used effectively in places with external shock, vibration, extrusion, thermal expansion, cold contraction and other phenomena, and can play a better role in silencing and expansion joints.

II. Simple operation and time saving:

1. Installation time is 3-5 times faster than that of welding, flange and thread, which greatly shortens the construction period.

2. No need for professionals, one hour of training can be used to reduce labor costs.

3. There are many types and specifications of products, which can meet the needs of site engineering in most occasions.

4. No special installation tools are needed. It can be disassembled and reused without maintenance.

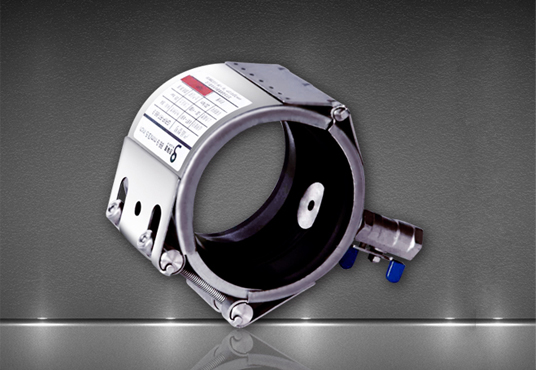

5. The joint of the connecting repair device can be rotated to select the optimum bolt position, even in narrow places.

III. Cost saving and high cost-effectiveness ratio:

1. Installation cost is easy to predict, calculation is more accurate, saving 20-40% of the manual installation cost.

2. Pipeline ports need not be expensive to handle, without a large number of skilled welders, welding cables and other personnel and equipment, easy installation.

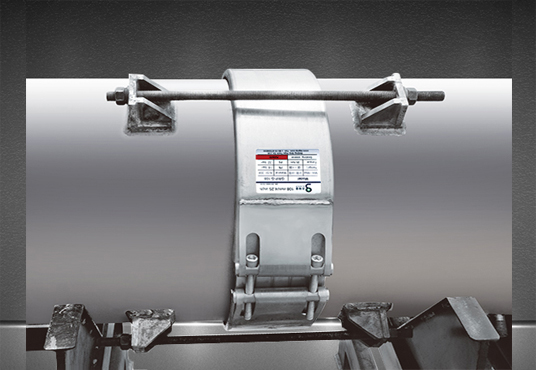

3. Light weight, simple and fast installation, no need to assemble itself, and no tedious adjustment and processing requirements for the connected pipelines. When installation, only the torque wrench is required to tighten 2-3 bolts from one side according to the prescribed torque, so the operation is particularly simple.

4. From the point of view of the whole project, the cost is lower than that of welding.

IV. Simple rewiring and easy disassembly and assembly:

1. Easy to maintain, can quickly clean the pipeline maintenance, pipe change and other work, the economy is very good.

2. Save installation space, suitable for complex space pipelines.

3. Avoid welding quality problems and work problems in the use process.

4. There is no welding slag in the pipe and no cleaning is needed, which avoids the problem of pipeline blockage in the use process and affects the normal life of residents.

V. Seismic, impact and noise reduction:

1. Change the traditional rigid connection to flexible connection, so that the pipe system is in the state of shock resistance and noise elimination.

2. The connection of flexible pipes allows the maximum deviation angle of the two pipes to be 10 degrees.

3. Absorbing the temporary rising force caused by thermal expansion and contraction or earthquake in long distance pipelines.

4. It can withstand the acceleration shock of 350g in 0.02 seconds and reduce the noise intensity by 60%. It is conducive to the safe and normal use of the whole pipe system, including pumps, valves and meters, and prolong the service life.

VI. Good safety, reliable quality and strong sealing performance:

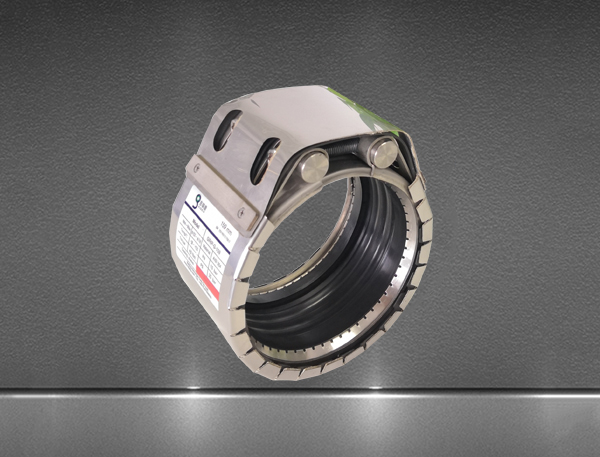

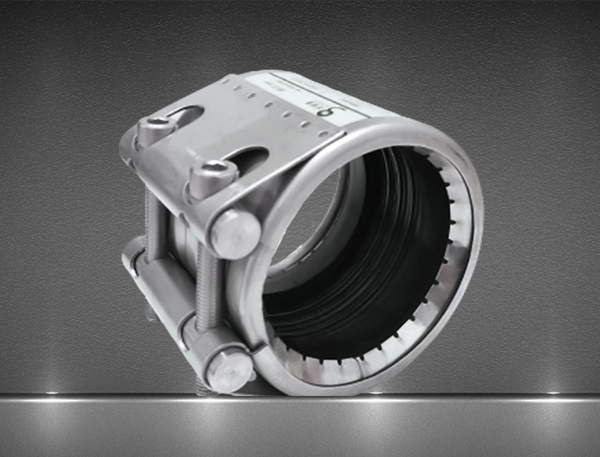

1. Because of the use of stainless steel shell and special material rubber ring, it can effectively prevent external drip corrosion and internal medium corrosion.

2. Because of the special structure at both ends of the rubber sealing cylinder inside the connector, the longer service life of the connector is guaranteed. The multi-stage lip-shaped convex ring plays a multi-stage sealing role in preventing fluid leakage from outside the pipeline.

3. Generally, it can withstand 16/c, and some can reach dozens of pressures. There will be no "three leaks" in long-term use.

4. Good safety, no fire hazards, installation and construction of the whole process without fire.

5. Quality problems caused by uneven welder quality and imperfect welder technology in non-welding system.

6. Quality can be guaranteed and controlled by any installation company.

VII. Wide range of applications:

1. Urban tap water, drainage, heating, fire protection and other pipelines, as well as temporary water pipelines for industry, mining, agriculture and construction, optical cable, cable joint protection, suitable for various seamless steel pipe, threaded pipe, cast iron pipe, plastic pipe, glass fiber reinforced plastic pipe connection and repair.

2. Pipeline connection of power equipment in industry, mining, workshop, Hotel and hotel for heat insulation or shock absorption.

3. Oilfield production plants, refineries, chemical plants, oil, gas and cooling water circulation pipeline systems.

4. Water supply and drainage and circulating pipeline systems of atomic energy, thermal power and hydraulic power plants.

5. Subway, basement, damp ground and buried pipeline system.

6. Cold storage and refrigeration equipment pipeline system.

7. Pipeline network system configuration engineering in shipbuilding.

8. Configuration and connection of pipeline system in locomotive manufacturing.